Midmark M9 Autoclave User Manual⁚ A Comprehensive Guide

This comprehensive guide provides a detailed overview of the Midmark M9 Autoclave, covering installation, operation, maintenance, troubleshooting, and safety precautions. It’s designed to help you understand and effectively use your M9 autoclave for reliable sterilization of instruments in your dental or medical practice. This manual covers all aspects of the Midmark M9, from loading and unloading instruments to selecting sterilization cycles and monitoring the process.

Introduction

Welcome to the Midmark M9 Autoclave user manual. This comprehensive guide is designed to provide you with all the information you need to operate, maintain, and troubleshoot your Midmark M9 autoclave. The Midmark M9 is a compact, easy-to-use, and reliable steam sterilizer that is ideal for small offices and clinics. It features a user-friendly interface, automatic water filling, and a range of sterilization cycles to meet your specific needs.

This manual will guide you through the process of setting up and operating your M9 autoclave, from loading instruments and selecting sterilization cycles to monitoring the process and performing routine maintenance. We have included detailed instructions, illustrations, and troubleshooting tips to make using your M9 autoclave as easy as possible.

Before using your Midmark M9 autoclave, please carefully read this manual. Familiarizing yourself with the features and operating procedures will ensure safe and effective sterilization of your instruments. If you have any questions or concerns, please contact Midmark customer support for assistance.

Overview of the Midmark M9 Autoclave

The Midmark M9 Autoclave is a compact, fully automatic steam sterilizer designed for efficient and reliable sterilization of dental and medical instruments. It features a user-friendly interface, automatic water filling, and a range of sterilization cycles to meet various needs. This autoclave boasts a small footprint, making it ideal for smaller offices with limited space. Its intuitive design allows for easy loading and unloading of instruments, making the sterilization process smooth and efficient.

The Midmark M9 utilizes steam under pressure to eliminate microorganisms and achieve sterilization. It features multiple sterilization cycles, including unwrapped, pouches, liquids, and packs, to accommodate different instrument types and packaging. The autoclave also includes safety features, such as a low water indicator light, a door-ajar light, and automatic shut-off mechanisms, to ensure safe and effective operation.

The Midmark M9 is designed to enhance your workflow while maintaining the highest standards of sterility. Its simplicity and reliability make it a popular choice for dental and medical professionals who prioritize efficient and effective instrument processing.

Key Features and Benefits

The Midmark M9 Autoclave is packed with features that enhance efficiency, safety, and ease of use. Its key features include⁚

- Automatic Water Filling⁚ The autoclave automatically fills with the appropriate amount of water, eliminating the need for manual filling and reducing the risk of errors.

- Pre-Programmed Cycles⁚ The M9 offers a range of pre-programmed sterilization cycles, including unwrapped, pouches, liquids, and packs, catering to various instrument types and packaging needs.

- Compact Design⁚ Its small footprint makes it suitable for even the smallest offices, maximizing space utilization.

- Easy-to-Use Interface⁚ The M9 features a simple and intuitive control panel for straightforward operation, making it easy for users of all experience levels.

- Fast Cycle Times⁚ The M9 boasts quick cycle times, allowing for efficient instrument processing and minimizing downtime.

- Safety Features⁚ The autoclave includes safety features such as a low water indicator light, a door-ajar light, and automatic shut-off mechanisms, ensuring safe and reliable operation.

These features translate into numerous benefits for users, including⁚

- Enhanced Workflow⁚ The automatic features and fast cycle times streamline the sterilization process, saving time and improving overall workflow efficiency.

- Improved Sterilization Quality⁚ Pre-programmed cycles and safety features ensure consistent and reliable sterilization results, promoting patient safety.

- Increased Productivity⁚ The efficient operation of the M9 allows for faster turnaround times, leading to increased productivity.

- Reduced Maintenance⁚ The autoclave’s design minimizes the need for frequent maintenance, reducing downtime and operational costs.

The Midmark M9 Autoclave is a valuable asset for any dental or medical practice looking to optimize sterilization processes and maintain the highest standards of safety and efficiency.

Installation and Setup

Proper installation and setup of your Midmark M9 Autoclave are crucial for ensuring its optimal performance and safety. The following steps outline the general process⁚

- Unpacking and Inspecting⁚ Carefully unpack the autoclave and inspect for any signs of damage during transit. Ensure all components are included, such as the power cord, water hoses, and user manual.

- Location Selection⁚ Choose a suitable location for the autoclave, ensuring it is on a level, stable surface that can support its weight. The area should be well-ventilated and free from excessive heat or moisture. Avoid placing it near flammable materials or sources of water.

- Water Connection⁚ Connect the water hoses to the autoclave and the water source, ensuring they are securely fastened. Refer to the user manual for specific instructions on water pressure and flow requirements.

- Electrical Connection⁚ Connect the power cord to a dedicated outlet that meets the autoclave’s electrical specifications. The outlet should be easily accessible and properly grounded for safety.

- Initial Run⁚ Once the autoclave is connected to water and electricity, run an initial cycle with distilled water to flush the system and remove any impurities. This helps ensure optimal performance and prevents potential issues.

- Calibration and Testing⁚ After the initial run, calibrate the autoclave according to the manufacturer’s instructions. This ensures accurate temperature and pressure readings for effective sterilization. Conduct a test run to verify proper operation.

- User Training⁚ Familiarize yourself and your staff with the autoclave’s operation and safety features by reviewing the user manual and attending any available training sessions. This ensures safe and efficient use of the equipment.

By following these steps, you can ensure the proper installation and setup of your Midmark M9 Autoclave, allowing for optimal performance and a safe sterilization environment.

Operating the Autoclave

Operating the Midmark M9 Autoclave is straightforward and designed for user-friendly sterilization. This section outlines the key steps involved in using the autoclave effectively and safely.

- Power On and Water Level Check⁚ Turn on the autoclave and ensure the water level is sufficient. The autoclave will automatically fill with water if necessary. If the water level is low, the autoclave will indicate this with a warning light or message.

- Loading Instruments⁚ Load the instruments into the autoclave chamber, following the manufacturer’s instructions. Ensure proper placement and avoid overcrowding, allowing steam to circulate effectively. Use sterilization pouches or wraps as needed to protect instruments and maintain sterility.

- Cycle Selection⁚ Choose the appropriate sterilization cycle based on the type of instruments and materials being sterilized. The Midmark M9 typically offers various cycles, such as unwrapped, pouched, liquids, and packs. Select the cycle that best meets your needs.

- Cycle Start⁚ Once the instruments are loaded and the cycle is selected, press the start button to initiate the sterilization process. The autoclave will automatically control the temperature, pressure, and duration of the cycle.

- Monitoring the Process⁚ Monitor the sterilization process through the autoclave’s display, which typically shows the cycle progress, temperature, and pressure readings. The autoclave will indicate the completion of the cycle with a visual or audible signal.

- Instrument Removal⁚ Once the cycle is complete, allow the autoclave to cool down for a safe temperature before opening the door. Remove the sterilized instruments carefully, ensuring they are handled aseptically to maintain sterility.

- Documentation⁚ Record the sterilization cycle details, including the date, time, cycle type, and any other relevant information, for documentation and tracking purposes.

By following these steps, you can operate the Midmark M9 Autoclave efficiently and safely, ensuring the sterilization of instruments for your medical or dental practice.

Loading and Unloading Instruments

Loading and unloading instruments into the Midmark M9 Autoclave is a crucial step in ensuring proper sterilization. This section provides a step-by-step guide for safe and efficient handling of instruments during this process.

- Prepare Instruments⁚ Before loading, ensure instruments are thoroughly cleaned and rinsed to remove any debris or contaminants. Any residual debris can interfere with sterilization and potentially compromise instrument sterility.

- Wrap or Pouch⁚ Wrap instruments in sterilization pouches or wraps, following the manufacturer’s instructions. This protects instruments from contamination during the sterilization process and maintains sterility after removal.

- Loading Procedure⁚ Open the autoclave door and carefully place wrapped instruments into the chamber. Avoid overcrowding the chamber, allowing steam to circulate freely around each instrument for effective sterilization.

- Placement Considerations⁚ Place instruments in a way that allows steam to penetrate all surfaces. Avoid stacking instruments, ensuring they are not touching each other or the chamber walls. This ensures proper heat and pressure distribution during the sterilization cycle.

- Close the Door⁚ Close the autoclave door securely, ensuring a tight seal for optimal sterilization. The door must be securely closed for the autoclave to function properly and maintain pressure within the chamber.

- Unload Instruments⁚ After the sterilization cycle is complete, allow the autoclave to cool down to a safe temperature before opening the door. Open the door slowly, ensuring instruments are not accidentally dropped or contaminated during removal.

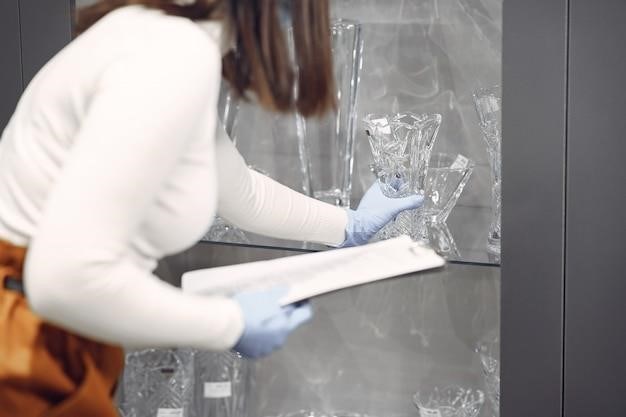

- Handling Precautions⁚ Handle sterilized instruments with care, avoiding contact with non-sterile surfaces. Use sterile gloves or forceps to prevent contamination and maintain the sterility of the instruments.

By following these guidelines, you can ensure safe and efficient loading and unloading of instruments into the Midmark M9 Autoclave, maximizing the effectiveness of the sterilization process and maintaining instrument sterility.

Selecting Sterilization Cycles

The Midmark M9 Autoclave offers a variety of sterilization cycles designed to meet specific needs. Selecting the appropriate cycle is crucial for effective sterilization and instrument longevity. This section provides a comprehensive guide to help you choose the right cycle for your specific requirements.

- Unwrapped Cycle⁚ This cycle is ideal for unwrapped instruments, typically used for surgical instruments or those requiring immediate use. It utilizes a high-temperature, high-pressure steam sterilization process to effectively eliminate microorganisms.

- Pouches Cycle⁚ This cycle is designed for instruments wrapped in sterilization pouches, commonly used for general dental instruments; The cycle ensures thorough sterilization while maintaining the integrity of the pouch for post-sterilization handling.

- Liquids Cycle⁚ This cycle is specifically designed for sterilizing liquids, commonly used for solutions or medications requiring sterilization. It utilizes a lower temperature and pressure compared to other cycles to prevent boiling or damage to the liquids.

- Packs Cycle⁚ This cycle is tailored for instruments packaged in sterilization packs, commonly used for larger instruments or those requiring extended sterility. The cycle provides a longer sterilization time to ensure thorough penetration of steam and effective sterilization.

Refer to the Midmark M9 User Manual for detailed cycle parameters and specific recommendations based on the type of instruments and packaging used. Understanding the different cycles and their applications will help you choose the most effective cycle for your specific sterilization needs, ensuring optimal instrument sterility and patient safety.

Monitoring the Sterilization Process

The Midmark M9 Autoclave features an intuitive control panel and visual indicators that allow you to effectively monitor the sterilization process, ensuring complete and reliable sterilization. This section provides guidance on interpreting the key indicators and understanding the stages of the sterilization cycle.

- Cycle Progress Display⁚ The control panel displays the progress of the selected sterilization cycle, indicating the current stage and remaining time. This allows you to track the cycle’s progress and anticipate its completion.

- Temperature and Pressure Readings⁚ The M9 displays real-time temperature and pressure readings throughout the sterilization cycle. These readings are crucial for verifying that the cycle is achieving the required sterilization parameters.

- Alarm Indicators⁚ The autoclave features various alarm indicators, such as a low-water alarm, door-ajar alarm, and cycle error alarm. These indicators provide immediate alerts for any malfunctions or issues during the sterilization process, allowing for prompt intervention and troubleshooting.

- Cycle Completion Signal⁚ Once the sterilization cycle is complete, the autoclave typically emits an audible signal or visual indication, notifying you that the cycle has finished and the instruments are sterile. This confirmation ensures that you are aware when the cycle is complete and the instruments are ready for use.

Regularly monitoring these indicators and understanding their significance will enable you to ensure the effectiveness and safety of the sterilization process. The Midmark M9 Autoclave provides comprehensive monitoring features that enhance the reliability and efficiency of your sterilization procedures.

Maintenance and Cleaning

Maintaining the cleanliness and functionality of your Midmark M9 Autoclave is essential for ensuring safe and reliable sterilization. Regular cleaning and maintenance procedures help prevent the accumulation of debris, mineral deposits, and potential contaminants. This section provides detailed instructions for daily, weekly, and monthly cleaning routines, ensuring that your autoclave remains in optimal condition.

The Midmark M9 Autoclave requires a combination of daily, weekly, and monthly cleaning procedures to maintain its performance and safety. These routine cleaning practices help prevent the accumulation of debris, mineral deposits, and potential contaminants, ensuring that your autoclave remains in optimal working order. The following guidelines provide a comprehensive approach to cleaning your Midmark M9 Autoclave⁚

- Daily Cleaning⁚ Wipe down the exterior surfaces of the autoclave with a mild disinfectant solution. Ensure that the door seals, chamber, and drainage system are free of any visible debris or residue.

- Weekly Cleaning⁚ Perform a more thorough cleaning of the chamber and drainage system. Use a specialized autoclave cleaning solution to remove any mineral deposits or build-up. Refer to the Midmark M9 Autoclave user manual for specific cleaning solutions and procedures.

- Monthly Cleaning⁚ Clean the interior of the chamber thoroughly, including the drainage system, with a specialized autoclave cleaning solution. Inspect the heating element for any signs of damage or wear. Replace the water filter if necessary, as recommended in the user manual.

Maintaining a consistent cleaning schedule will significantly prolong the life of your Midmark M9 Autoclave and ensure its continued reliable performance.

Daily Cleaning

Daily cleaning is an essential part of maintaining the functionality and hygiene of your Midmark M9 Autoclave. It involves a quick and straightforward process that helps prevent the accumulation of debris, fingerprints, and other contaminants on the exterior surfaces of the autoclave. This routine cleaning procedure is crucial for ensuring the longevity and reliable performance of your equipment.

The daily cleaning of your Midmark M9 Autoclave should be performed after each sterilization cycle, or at least once a day. This routine maintenance helps maintain the cleanliness of the autoclave and prevent the build-up of debris and contaminants. The following steps outline the daily cleaning process⁚

- Wipe down the exterior surfaces⁚ Use a clean, soft cloth dampened with a mild disinfectant solution to wipe down the exterior surfaces of the autoclave, including the control panel, door, and sides. Pay attention to any areas that are prone to fingerprints or smudges.

- Clean the door seals⁚ Carefully wipe down the door seals with a damp cloth to remove any debris or residue. Ensure that the seals are free of any visible contaminants.

- Inspect the drainage system⁚ Visually inspect the drainage system for any signs of blockage or leakage. If necessary, clear any visible debris from the drainage system.

By following these simple daily cleaning steps, you can ensure that your Midmark M9 Autoclave remains clean, hygienic, and in optimal working condition.